Architects: Need to have your challenge featured? Showcase your work by importing initiatives to Architizer and join our inspirational newsletters.

Materials decisions are a serious a part of each challenge. From travertine to limestone, corten metal to zinc, timber to terrazzo, architects spend an enormous period of time and vitality choosing the right supplies for his or her designs. Sadly, not all of the supplies utilized in a challenge are chosen. Some drive their means into the constructed setting, not by design intent however by sheer industrial extra.

In occasions of want, the world has all the time turned to structure to find numerous ingenious methods of absorbing industrial byproducts. The Romans strengthened their concrete with volcanic ash as a result of it was plentiful and a nuisance. In Nineteenth-century Northern Britain, slag bricks, in any other case referred to as Scoria brick, had been manufactured as iron manufacturing ramped up. Their dense, blackened surfaces had been a direct product of the plentiful steelworks waste of the age.

When the Second World Conflict left European cities in ruins, reconstruction relied on crushed rubble and salvaged supplies. Cities like Warsaw, Rotterdam and Berlin remade themselves from their very own stays. Whereas in Britain, bomb-damaged buildings had been pulverized and re-formed into new bricks, recycling historical past into the following iteration of town. For hundreds of years, “ghost supplies,” that are produced inadvertently by business, have been simply as a lot part of development as any consciously chosen stone or metallic. Ghost supplies take what’s leftover and undesirable and provides it objective.

Proper: Cakelot1, Whitby Scoria Bricks 1, CC BY-SA 4.0 | Left: Picture of Scoria brick in York taken by writer.

The development business is without doubt one of the largest producers of waste supplies, so architects and builders are more and more on the lookout for smarter methods to reincorporate their waste into new constructions. Demolition rubble is being crushed for combination, whereas discarded concrete is recast into precast panels. Previous bricks, as soon as thought of too labor-intensive to salvage, at the moment are cleaned, sorted and reused at scale. In the meantime, timber offcuts and sawdust are compressed into structural components and insulation.

Supplies that had been as soon as tough to recycle are additionally making their means again. Contaminated plasterboard waste can now be processed and remade into new gypsum panels. Inflexible foam insulation, usually stripped out throughout renovations, is salvaged quite than changed. Even offcuts of cross-laminated timber (CLT) and laminated veneer lumber (LVL), beforehand thought of too complicated to reuse, are being reassembled into new engineered wooden merchandise as a substitute of going to waste.

FRONT’S Fairly Plastic Panels | Picture by Nienke Krook courtesy of FRONT

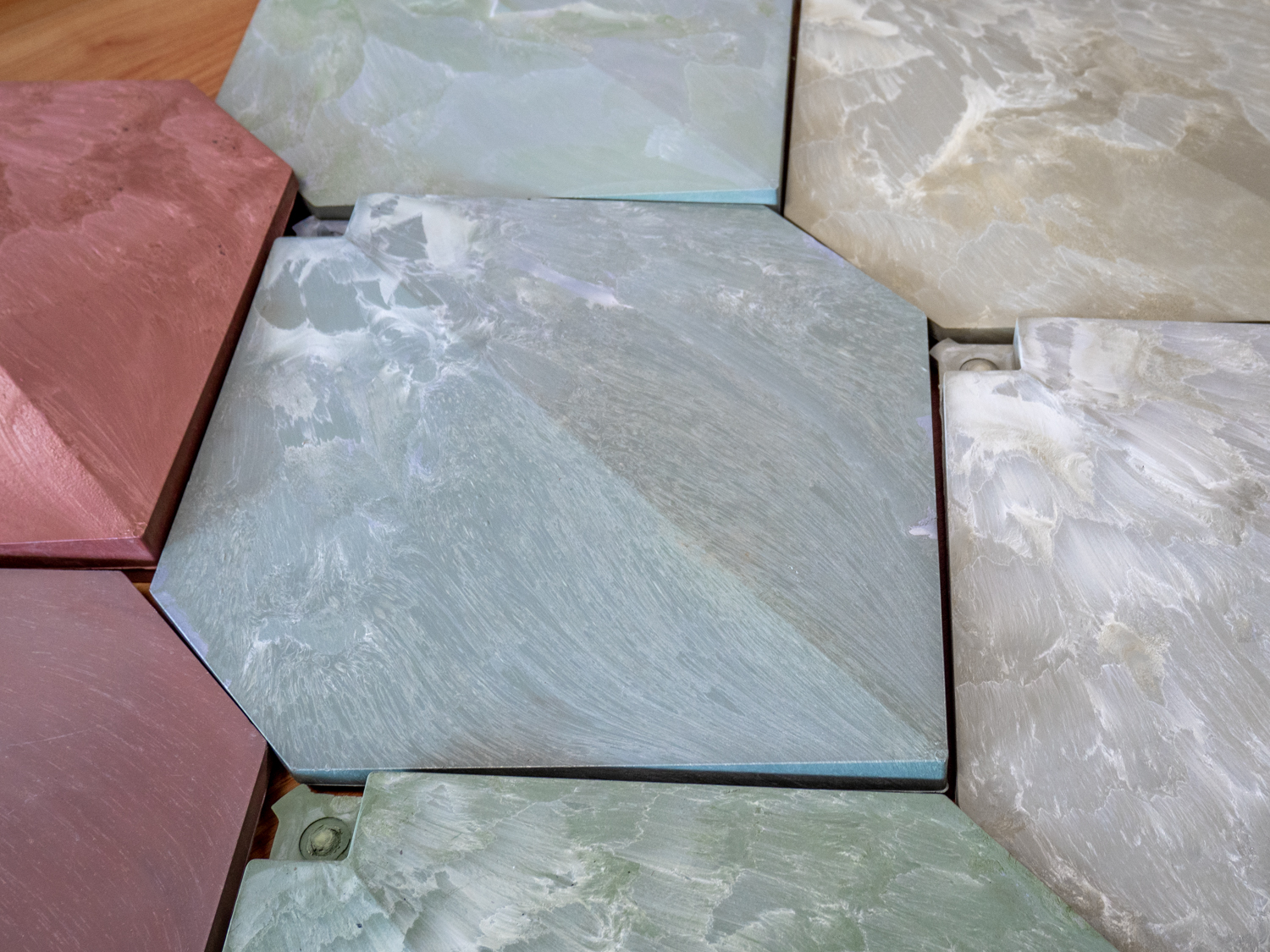

Firms like FRONT are discovering new methods to return development waste again into the constructed setting. Their WasteBasedBricks are made utilizing demolition rubble from city deconstruction websites and provides a second life to supplies that might in any other case be crushed into low-grade combination. Their Skip Tiles, composed of 95% recycled ceramics, reuse discarded offcuts and damaged tiles from tile producers, lowering the waste produced in fabrication. Even PVC waste from development websites, beforehand tough to recycle as a consequence of its chemical composition, is being repurposed into Fairly Plastic Panels, a cladding materials for ventilated façades and rainscreens.

Ghost supplies could also be rising in popularity, however their unreliability is the primary cause they continue to be secondary supplies quite than main ones. In contrast to quarried stone, precision-mixed concrete, or engineered timber — every manufactured to strict tolerances — development byproducts could be inconsistent, chemically unstable, and tough to standardize. The problem is not only the way to combine them, however the way to account for his or her unpredictability.

Recycled concrete combination (RCA), as an example, must be a simple substitute for virgin combination. In apply, its variable porosity, residual cement content material and embedded contaminants make it tough to manage. Previous concrete usually comprises alkali-silica reactions (ASR), which trigger unpredictable enlargement and cracking in new concrete mixes. Water absorption charges are increased than in pure stone aggregates, which means RCA should be utilized in fastidiously managed proportions to stop shrinkage and structural instability. Until examined batch by batch, no two recycled concrete aggregates behave precisely the identical. Within the Netherlands, New Horizon City Mining has been tackling this concern by creating strategies to extract and refine RCA with higher consistency, permitting it for use extra reliably in structural functions.

Anne & Max, Haarlem, Netherlands | FRONT’s Waste Based mostly Bricks, Glazed Bricks | Picture by Sheena Schouwink courtesy of FRONT

Recycled gypsum presents related challenges. Whereas the fabric itself is infinitely recyclable, plasterboard waste is never clear. It usually comprises paper fibers, residual adhesives, fireplace retardants and even contaminants like lead paint or mildew spores, relying on its supply. When reprocessed, these impurities should be eliminated or stabilized. A time-consuming and dear course of that makes virgin gypsum the extra enticing possibility in lots of circumstances. Within the UK, British Gypsum has launched a closed-loop recycling system for its plasterboard merchandise, guaranteeing that offcuts from development websites could be collected, cleaned and reintegrated into new gypsum board manufacturing with minimal lack of high quality. Nonetheless, this solely works when waste is fastidiously separated on-site. As soon as blended with common development particles, plasterboard turns into too contaminated to recycle.

Timber presents its personal set of points. Reclaimed wooden, particularly from demolition websites, is liable to warping, uneven moisture content material and historic chemical remedies that could be unsuitable for indoor use. Timber offcuts from fashionable manufacturing, equivalent to CLT and LVL remnants, are structurally sound however irregularly formed, making them tough to combine into standard framing programs. That is why many wooden byproducts are compressed into chipboard or engineered panels quite than reused of their unique kind — not as a result of they lack energy, however as a result of they lack standardization. In Germany, Gutex has developed a system to show sawmill byproducts and wood-processing waste into high-performance wooden fibre insulation, an method that ensures even the smallest timber remnants are utilized in a significant means.

Then there may be the difficulty of regulation. Most constructing codes are nonetheless based mostly on supplies behaving in predictable methods. A metal beam has a identified yield energy, a fired brick has a constant compressive energy, and a concrete combine is designed to treatment to a exact specification. Ghost supplies, in contrast, include unknowns. Recycled aggregates usually face decrease structural classifications as a result of their previous life impacts their long-term efficiency. Reclaimed metal is topic to stricter inspection requirements than newly cast beams, even when its metallurgical properties are similar. Recycled plastics are not often accredited for load-bearing functions as a result of their molecular construction degrades with every recycling cycle, introducing brittleness over time.

This regulatory hesitation could also be seen as bureaucratic resistance however in actuality it’s a obligatory safeguard in opposition to structural failure. Supplies with unknown histories or variable efficiency traits introduce dangers that architects and engineers can’t all the time quantify. Whereas this doesn’t imply ghost supplies are unsuitable for development, it does imply that structure should rethink the way it designs with them.

FRONT’s Fairly Plastic Panels | Picture by Nienke Krook courtesty of FRONT

At ETH Zürich’s Digital Building Lab, researchers are exploring how robotic fabrication can create extremely exact constructions from irregular recycled supplies. As a substitute of treating reclaimed components as faulty, their method makes use of digital modelling to work with materials inconsistencies, enabling them to suit collectively seamlessly in a managed development course of. This methodology reduces waste and ensures that every part is used effectively quite than being discarded for failing to satisfy conventional industrial requirements.

The truth is ghost supplies are a wonderful technique to scale back the extreme waste within the development business. As materials shortages and environmental considerations push us in the direction of circularity, structure is being requested to have interaction with them in a brand new means. The query is now not merely the way to repurpose waste, however the way to construct with it intelligently and safely.

Architects: Need to have your challenge featured? Showcase your work by importing initiatives to Architizer and join our inspirational newsletters.

High photograph: FRONT’s Fairly Plastic Panels courtesy of FRONT