After I suppose about plastics, one thing doesn’t add up. As soon as imagined as a accountable substitute for pure supplies, their actuality speaks of disconnection from supplies, labour and duty.

Petrochemical plastics, the supplies we instinctively affiliate with the phrase “plastic,” had been first created as brokers of conservation. In 1869, celluloid emerged as an industrial resolution to a organic disaster, changing ivory in billiard balls, piano keys, and luxurious items to curb the slaughter of elephants. These early artificial supplies provided a sort of technological idealism: to chemically replicate nature’s rarest substances and relieve stress on fragile ecosystems.

However in addressing one type of extraction, we accelerated one other. From this level, plastics quickly developed into engines of mass manufacturing and mass disposability. Right this moment, they’re among the many most pervasive pollution on earth, vastly overshooting their meant lifespans. Of all plastic ever produced, lower than 10% has been recycled.1,2 The remaining endures – dispersed into oceans, soils, atmospheres and our bodies.

Paradoxically, the uncooked materials that feeds this proliferation, petroleum, is itself reworked biology: historical microalgae, plankton, and microorganisms compressed over a whole bunch of thousands and thousands of years. Fossil fuels include the condensed stays of a few of Earth’s earliest organisms, predating forests, mammals, even vertebrates. But, we liquefy, refine, and discard these historical supplies to fabricate short-lived packaging, textiles, signage and constructing finishes.

We hardly ever account for his or her true value. In 2023, the Worldwide Financial Fund estimated that fossil gas industries obtain US$7 trillion in subsidies yearly, embedding the oil economic system, and its downstream plastics, deeply into international markets.3 Extraction is subsidised; waste is externalised.

In 2021, as I adopted the increasing conversations round petrochemical extraction, toxicity, and waste, I reached a degree the place passive participation was not tenable. My creative apply – initially rooted in artwork and materials analysis – shifted towards a extra centered enquiry: how may we think about an alternate system of creating, one that is still inside dwelling organic cycles, slightly than exploiting deep-time reserves?

This led to the founding of Different Matter, a research-led design studio working on the intersection of fabric innovation and sustainable futures. Our studio collaborates with architects, designers, and types searching for to combine sustainable, high-performance supplies into their tasks.

We provide bespoke session on materials suitability, technical specs, and software methods, in addition to prototyping and manufacturing. We’re centered on reimagining materials manufacturing for inside structure in addition to momentary purposes in retail, occasions and exhibitions.

On the centre of this query is the polymer itself: the elemental constructing block of plastics. Lengthy chains of repeating molecules that, relying on their construction and components, could be made versatile, inflexible, translucent, flame-resistant or extremely steady. In petrochemical plastics, these properties are achieved by means of a fancy matrix of chemical components: plasticisers, UV stabilisers, pigments, PFAS, phthalates, and biocides. Over time, these components migrate out of the polymer, leaching into air, soil, water and finally into organic methods.

This migration introduces toxicological challenges that cascade far past design intent: endocrine disruption, reproductive toxicity, immune system interference, and microbiome destabilisation, each inside human our bodies and throughout ecological methods. We dwell with these penalties every day, although they continue to be largely invisible within the objects and surfaces that populate fashionable life.

I started seeing these materials logics embedded in all places, together with my very own apply. As an exhibition maker, momentary exhibition graphics had been notably current. Minimize vinyl lettering utilized to gallery partitions are sometimes fabricated from PVC, a plastic deeply entwined with toxicity at each stage of its lifecycle. As soon as I absolutely understood this, I may not take part in its use, significantly because the writing on the wall introducing my work.

PVC carries an invisible moral weight that I couldn’t reconcile. Its manufacturing emits dioxins and dangerous by-products that persist in ecosystems for generations. Its components complicate recycling. At end-of-life, incineration and landfilling launch further toxins. Even throughout use, PVC emits risky compounds that compromise indoor air high quality. Its lifecycle is at odds with the very environmental ethics that first motivated plastics’ invention.

It was at this level {that a} essential collaboration with native signal producers started. Working with Growth Studios, a Melbourne-based manufacturing home, we produced the primary prototypes of what would develop into OM Signage Movie, reworking my creative enquiry right into a supplies studio devoted to non-petrochemical alternate options.

Different Matter and the seek for regenerative materials methods

Right this moment, we discover ourselves inside a sort of inversion. The place artificial plastics as soon as sought to duplicate nature’s supplies, we now look once more to nature to restore what synthetics have disrupted.

At Different Matter, our work with non-petrochemical polymers and natural compounds shouldn’t be nostalgic for purity however an try to proceed that unique mission of substitution – with full recognition of its penalties. Technically, we’re capable of obtain the high-spec floor qualities lengthy related to plastics: smoothness, translucency, lightness, flexibility. Qualities architects and designers proceed to worth for his or her management over floor, mild, and kind. Whether or not utilized in interiors, retail environments, or momentary installations, our materials methods are designed to fulfill each aesthetic and ecological standards, and we work intently with purchasers to tailor options to mission wants.

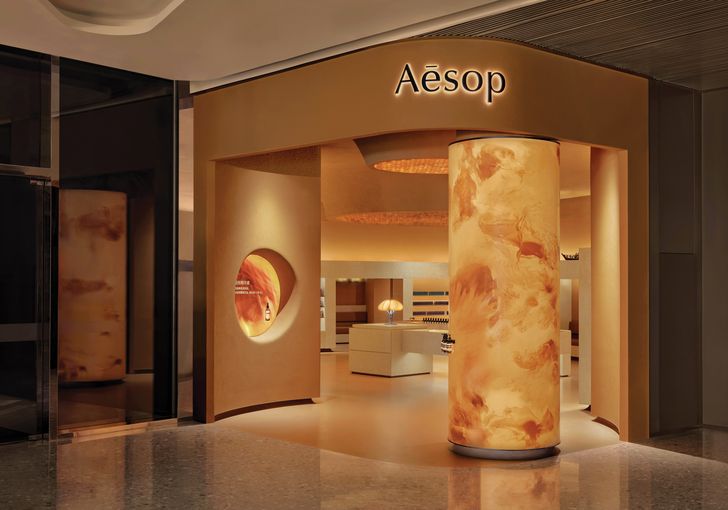

In our first main architectural fee, Aēsop’s Hainan retailer in China, accomplished in 2024, we developed two purposes of our algae- derived polymer system. The primary was a sealed architectural end, hand-cast onto over 2,000 aluminium panels suspended as ceiling oculi, evoking the refracted mild of the island’s marine surrounds. The second was a large-scale architectural movie, developed utilizing patent- pending expertise, able to being adhered with out adhesives to clean surfaces, wrapping the shop’s sculptural four-metre entrance column and translucent facade set up.

Hainan’s local weather posed distinctive challenges. Algae-based polymers are naturally hydrophilic, that means they take in moisture readily – a difficulty for longevity in tropical humidity. Working in session with conservation scientists at The Metropolitan Museum of Artwork, we developed a biodegradable sealing system that stabilises the fabric whereas preserving its recyclability.

Past the fabric science, the logistics advised their very own story. In a world the place architectural surfaces like quarried marble are shipped as heavy slabs throughout oceans, our architectural movie was rolled into poster tubes, vastly decreasing transport emissions and embodied carbon. Because of the liquid-formed course of of creating, we’ve been capable of create deep, fluid patterning harking back to marble, however with out the environmental value of extraction.

Via our proprietary non-petrochemical polymer methods, we’ve designed for circularity: supplies meant for reuse, restore, and remanufacture.

Their flexibility has allowed us to adapt throughout various climates, from managed interiors to tropical humidity. The fabric’s non-adhesive properties provide architects and designers a sort of reversibility hardly ever permitted in up to date fit-outs. Already deployed internationally, these supplies exhibit that high-spec efficiency and ecological duty usually are not mutually unique.

Different Matter’s methods are manufactured in Melbourne utilizing low-energy, non-industrial processes. Offcuts are retained and recycled, and each element is designed to assist disassembly, reuse and round restoration. Since its debut, the system has been deployed in additional Aēsop shops as an interchangeable movie utilized to entire partitions of glazing, demonstrating its business scalability and trade relevance.

Different Matter welcomes collaborations throughout scale and context. We accomplice with forward-thinking design groups, studios and types all in favour of round, non-toxic approaches to floor finishes and show purposes. When engaged early in a mission’s lifecycle, we’re capable of discover accountable alternate options to standard supplies from preliminary specification by means of to supply and disassembly.

In 2024, Different Matter’s work obtained recognition from Australia’s federal science company (CSIRO) and we had been awarded the Most Promising Development in Reaching the Ending Plastic Waste Mission Purpose, an acknowledgment aligned with Australia’s nationwide obligations beneath the UN Treaty on Plastic Air pollution. Our ongoing analysis partnership with the CSIRO focuses on the commercial scaling of manufacturing and advancing compostability certification to stability development with ecological duty.

The place does this go away us?

Plastics’ histories are nonetheless transient, relative to the deep-time biology they descend from. We’re, in some ways, nonetheless adolescents in our relationship with these supplies. The petrochemical plastics that dominate the constructed atmosphere have allowed unprecedented materials expression, however they’ve additionally burdened us with monumental well being, environmental, and planetary prices.

Pioneering work by Alison Mears and Jonsara Ruth at Parsons’ Wholesome Supplies Lab in New York is establishing a brand new benchmark for transparency and rigour in materials evaluation.

Via unbiased, design-led analysis, the lab identifies and communicates the often-obscured dangers embedded in generally specified constructing merchandise. A group of postdoctoral fellows leads forensic investigations into these supplies, contributing to a frequently up to date matrix of vetted alternate options, offering architects and designers with each the data and instruments to make more healthy, extra accountable selections.

We’re starting to mature. The trail forward won’t be outlined by a singular breakthrough however a broader cultural shift: one which recalibrates our relationship to the supplies we make our world with, towards reversibility, repairability, and systemic consequence.

Because the urgency for accountable materials options grows, we invite architects and specifiers to hitch us in shaping a constructed atmosphere that aligns with regenerative ideas.