Architects: Wish to have your undertaking featured? Showcase your work by importing tasks to Architizer and join our inspirational newsletters.

“Complete Home 3D Printed in 24 Hours,” “Robots Construct Houses from Clay,” “World’s First 3D-Printed Neighborhood Launches.”

Keep in mind these headlines? Until you have been residing beneath a rock (an actual or 3D-printed one, it doesn’t actually matter), you in all probability noticed a couple of of them a few years again.

For a second, it appeared like 3D printing was about to revolutionize structure. In any case, it promised sooner, cheaper and extra sustainable development on the push of a button. Whereas the expertise itself was not precisely new, this was the primary time it was being taken critically throughout the structure world. Architects, engineers and tech fanatics alike described it as the brand new “it” software of the constructed setting.

However as we are able to clearly see at present (most of us nonetheless not residing in 3D-printed homes and all), the novel transformation promised by these early experiments by no means fairly took maintain — at the least not in the way in which individuals anticipated. That doesn’t imply the expertise vanished, although. In truth, it’s been doing one thing arguably extra impactful: discovering its place not in printing total buildings, however in refining their particulars.

This piece seems at how 3D printing entered the trade, why the early hype pale and the way it’s now quietly (however efficiently) proving its worth in architectural design.

3D Printing Earlier than It Was Cool

Whereas it would’ve hit the architectural headlines within the 2010s, 3D printing has been round for much longer. The expertise first emerged within the Eighties as a software for speedy prototyping in industrial design. Engineers used it to check product components with out the time and value of conventional manufacturing. It wasn’t glamorous, nevertheless it was environment friendly, laying the groundwork for what would ultimately develop into a game-changer throughout a number of industries.

All through the ’90s and early 2000s, 3D printing quietly expanded its attain. Aerospace and automotive firms started utilizing it to develop light-weight components. The medical discipline began experimenting with customized implants and prosthetics. Product designers cherished it for the liberty it gave them to iterate shortly and take a look at advanced kinds with out costly tooling.

Structure, nevertheless, took somewhat longer to affix the celebration. At first, 3D printing was principally used behind the scenes to be used circumstances like designing bodily fashions, idea research and competitors entries. Nonetheless, at that time, it was a software for visualization fairly than development. However because the machines obtained greater and the supplies extra formidable, architects began questioning what would occur if as an alternative of simply utilizing this expertise for printing fashions of buildings, they tried to make use of it for the true factor as an alternative.

This began with early experiments like small pavilions, robotic clay extrusions and concrete wall prototypes in labs, which sparked a wave of curiosity and hypothesis. It felt like the start of one thing main. And in a manner, it was.

The Rise and Fall of 3D-Printed Buildings

As soon as 3D printing caught the structure world’s consideration, the ambitions obtained huge. Quick. The thought of printing total buildings was being critically pitched as an answer to pressing, real-world issues. It was positioned as a repair for challenges just like the demand for quick, low-cost housing in catastrophe zones and the rising want for modular items in quickly increasing cities, providing faster builds, minimal labor and fewer materials waste.

In 2017 development firm Apis Cor made headlines for printing a full home in simply 24 hours utilizing a cell concrete printer. ICON, based mostly within the U.S., centered on inexpensive housing, partnering with non-profits to 3D print properties in underserved communities.

In the meantime, WASP in Italy developed machines that extrude regionally sourced clay to print natural, zero-waste constructions, even experimenting with off-grid, village-scale residing.

The imaginative and prescient was daring and, for some time, genuinely thrilling. However on the bottom, the truth was extra sophisticated.

For one, supplies posed an issue. Most printed constructions relied on a kind of extruded concrete or clay (each supplies that aren’t at all times nice at dealing with insulation, structural hundreds or weathering on their very own). Add to that the necessity to manually combine plumbing, electrical energy, home windows and finishes, and immediately the “absolutely automated construct” doesn’t look so absolutely automated.

Then there have been regulatory points. Constructing codes, zoning legal guidelines and allow processes have been (and nonetheless are) created round conventional constructing strategies. In lots of locations, there merely wasn’t a framework to judge or approve a 3D-printed constructing.

And at last, there was the aesthetic and design problem. Whereas the layered, ribbed look of extruded concrete had a sure novelty at first, it shortly turned repetitive. Customization was doable, however costly. In observe, most printed buildings ended up wanting like variations of the identical thought.

So whereas the expertise was promising, the programs round it weren’t able to catch up. However the trade didn’t reject 3D printing; it simply wanted to determine the place it really made sense. And because it seems, that “sense” was hiding within the smaller, extra intricate components of buildings, not the shells themselves.

From Printing Buildings to Perfecting the Particulars

Ceramic Home by Studio RAP, Amsterdam, Netherlands

Ceramic Home by Studio RAP, Amsterdam, Netherlands

Because the early pleasure round large-scale 3D printing collided with actuality, the restrictions turned clear.

However as an alternative of abandoning the expertise, architects and researchers started making use of it the place it could possibly be simpler: producing parts fairly than total buildings. The shift moved 3D printing from construction to element, the place precision, variation and small-batch manufacturing should not simply acceptable however usually most popular.

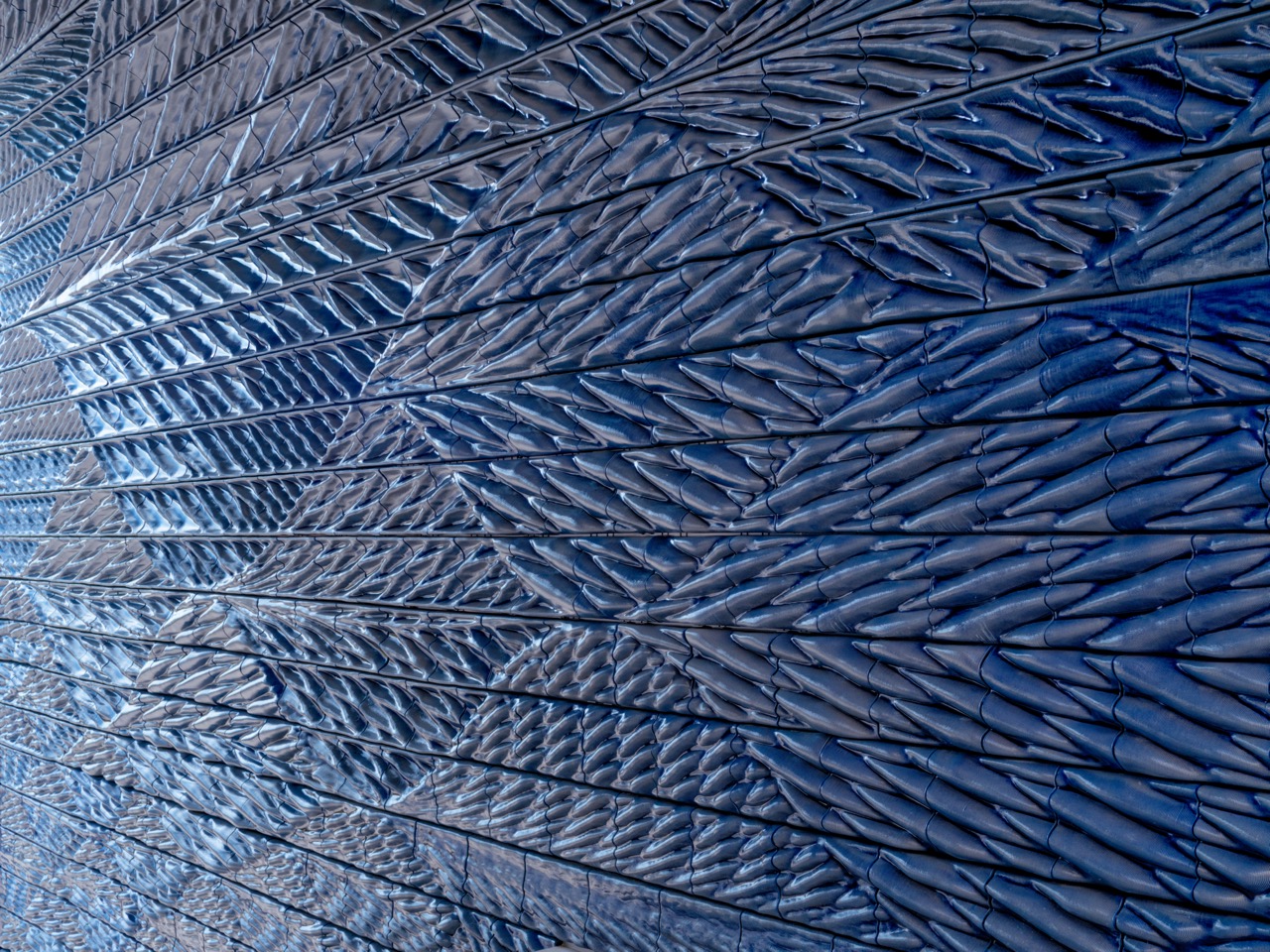

New Delft Blue by Studio RAP, Delft, Netherlands

This modification aligned effectively with computational design instruments. Parametric workflows allowed architects to generate a whole lot of variations of a component, adapting geometry and sample in response to environmental or structural inputs. 3D printing made it possible to manufacture these non-standard parts with out molds or in depth tooling. The outcome was a rising curiosity in utilizing the expertise for cladding panels, tiles, joints and different expressive constructing components.

This modification aligned effectively with computational design instruments. Parametric workflows allowed architects to generate a whole lot of variations of a component, adapting geometry and sample in response to environmental or structural inputs. 3D printing made it possible to manufacture these non-standard parts with out molds or in depth tooling. The outcome was a rising curiosity in utilizing the expertise for cladding panels, tiles, joints and different expressive constructing components.

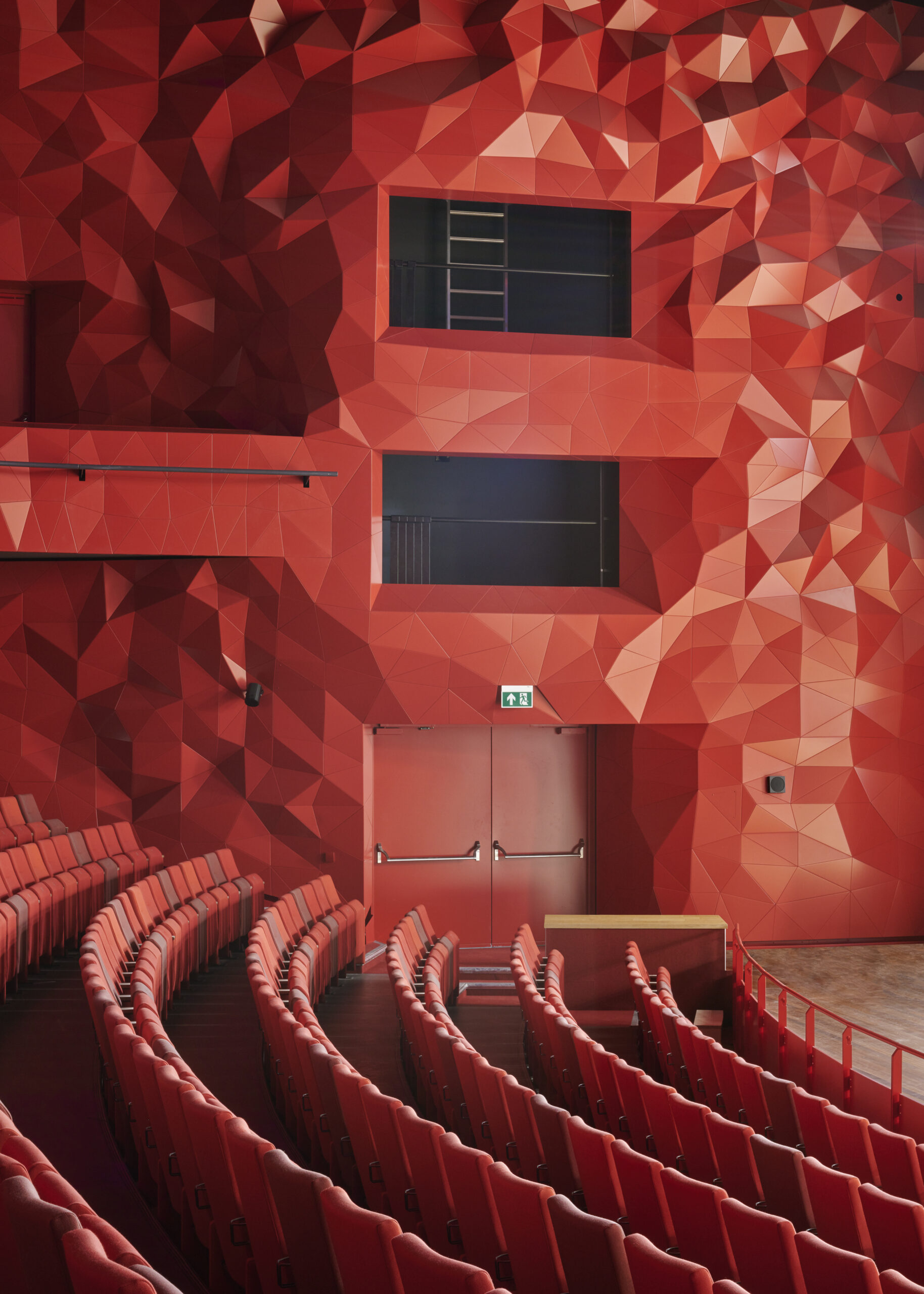

Studio RAP has adopted this strategy throughout a number of tasks, utilizing robotic 3D printing to provide ceramic façade programs with advanced geometry. In New Delft Blue and Ceramic Home, conventional glazing methods are mixed with digitally generated kinds. Their different tasks like Theater Zuidplein combine decorative surfaces and customized tiling straight into the structure.

HiLo Unit at NEST by ETH Zurich, Block Analysis Group, Dübendorf, Switzerland

HiLo Unit at NEST by ETH Zurich, Block Analysis Group, Dübendorf, Switzerland

At ETH Zurich, the Block Analysis Group has explored 3D printing in structural and formwork programs. The HiLo Unit on the NEST constructing used light-weight printed formwork to forged optimized concrete shells. In Striatus, a 3D-printed masonry bridge designed by Zaha Hadid Architects was assembled with out reinforcement or mortar, counting on compression-based design.

MX3D, recognized for robotic steel printing, created a full-scale pedestrian bridge in Amsterdam utilizing printed metal parts. The undertaking demonstrated how steel additive manufacturing can be utilized for infrastructural components with advanced geometries.

In every of those circumstances, 3D printing didn’t purpose to exchange standard development however to help it, permitting for complexity, customized match and materials precision the place it provides essentially the most worth.

A Quiet Success

What 3D printing has confirmed, over time, is that it doesn’t must overhaul the development trade to be priceless. It simply wanted to search out the proper scale. In any case, the main points of a undertaking that give it texture, identification, or delicate complexity will be simply as vital because the constructing itself.

3D printing permits a degree of ornamentation and materials specificity that fashionable development strategies usually wrestle to justify. Tiles can reply to sunlight patterns. Joints can observe parametric logic. Surfaces will be formed to go well with their context with out counting on mass manufacturing.

Theater Zuidplein by Studio RAP, Rotterdam, Netherlands

This strategy displays broader shifts in structure. There’s a transfer towards round design, a renewed curiosity in native supplies and methods, and a reliance on digital workflows that embrace variation and responsiveness. In that context, 3D printing now not looks like a futuristic gimmick. It’s merely a software getting used with objective.

And as architectural observe continues to evolve, we’ll doubtless see much more inventive, sustainable and built-in makes use of for 3D-printed particulars. Relaxation assured: the 3D printing revolution didn’t vanish. It simply zoomed in.

Architects: Wish to have your undertaking featured? Showcase your work by importing tasks to Architizer and join our inspirational newsletters.